| Author | Message | |||

xujian (zdp1979) Junior Member Username: zdp1979 Post Number: 3 Registered: 01-2007 |

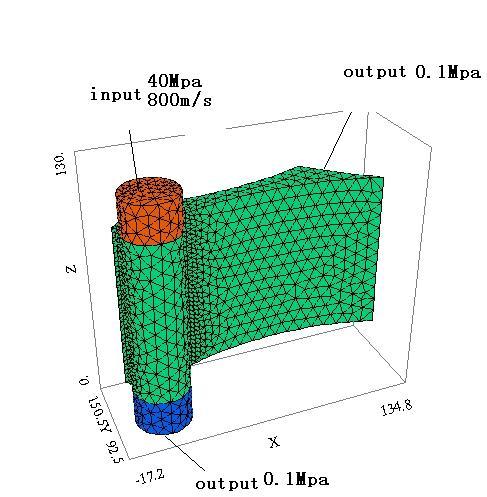

dear Nelson. the model picture and the model.pde is as uploaded. the problem is 3 dimensional flow. i want to simulate the conditions as follows: one input hole and two output hole. others are side walls. and the boundaries conditions are given as the pictures shows. and in the pde file, i have converted the unit. the units are mm-g-ms. i set the control and initial value as the example "3d-flowbox". but it runs and the results doesn't converge. the velocity contour is not smooth and the velocity in the fact can't get so large. what's wrong about this problem. can you give me some advice. thanx a lot.

| |||

xujian (zdp1979) Member Username: zdp1979 Post Number: 4 Registered: 01-2007 |

the above picture, the orange part of input and the blue part of output, as the code, should be changed. i am sorry to explain this. | |||

Robert G. Nelson (rgnelson) Moderator Username: rgnelson Post Number: 747 Registered: 06-2003 |

Your initial conditions specify zero velocity and a pressure ramped in z. This means that when the solution process starts there is a massive acceleration downward for all the fluid. Once having shocked the system in this way, the trial solution becomes chaotic, and the iteration cannot recover. With a tiny viscosity, there is no way to diffuse the errors and converge to a solution. I suggest that, rather than staging the density on and off, you instead specify the correct density and stage the viscosity. Start with a very high viscosity to diffuse the errors in the initial conditions, and then stage it down toward the target value. If the ultimate Reynolds number in the system is very high, you may not be able to get the viscosity down as far as you want. Include some history plots of pertinent values (like vz in the horn) to monitor how the charactistics progress with decreasing viscosity. You may find that a viscosity higher than the target value produces a solution sufficiently close to the correct solution. | |||

Robert G. Nelson (rgnelson) Moderator Username: rgnelson Post Number: 752 Registered: 06-2003 |

Also, if the PENALTY is too high, it makes the equations very stiff. Try reducing the Penalty coefficient a bit. | |||

xujian (zdp1979) Member Username: zdp1979 Post Number: 5 Registered: 01-2007 |

thanx very much. i think i get what you have advised. |